The PressClean USA team has over 30 years of experience in press refurbishment. Our detailed, certified process ensures that your press returns to you in like-new condition, ready to provide you with years of additional, reliable service. All PressClean USA Certified Press Refurbishments Come With A Heidelberg Parts and service credit which never expires.

The PressClean USA Certified Refurbishment Process:

- Machines are stripped, (all parts are systematically marked and palletized for each individual unit).

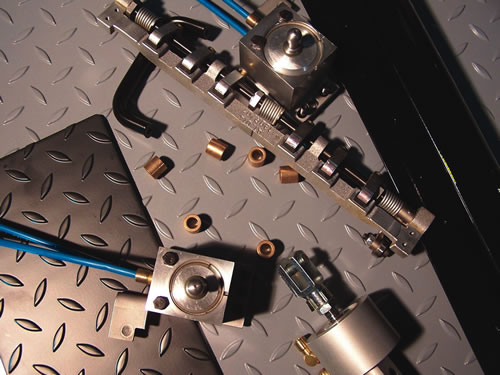

- Grease and loose particles are eliminated through our state-of-the-art pressure island system using chemically enhanced rust inhibiting agents.

- State-of-the-art Cryocleaning (CO2) is performed.

- The press and all ancillaries such as cabinets, CPC, pumps etc., the press goes to our hand cleaning bays for the removal of stubborn inks and stains.

- The immaculately clean press is then painted (Heidelberg gray, for example, is imported directly from Germany) to the original finish.

- Items such as catwalks, guards, red nipper bars and ink are powder coated to provide the highest degree of durability against chemicals and everyday wear and tear.

- Our transparent, Heidelberg certified inspection process ensures the delivery of a top-quality press.

- If required, the press can be re-assembled for print test in our state-of-the-art demonstration showroom.

- Prior to shipment, the press is given a final wipe-down, anti-rust treatment, is fully greased, stretch wrapped and readied for transport to the customer.

- Each certified press undergoes over 375 checks to insure a quality product for our customer.

When the refurbishment process is completed, you can print test your like-new machine in our impressive 40,000 square foot, state-of-the-art facility.

For more information about the certified PressClean USA refurbishment process, contact one of our dedicated team members.